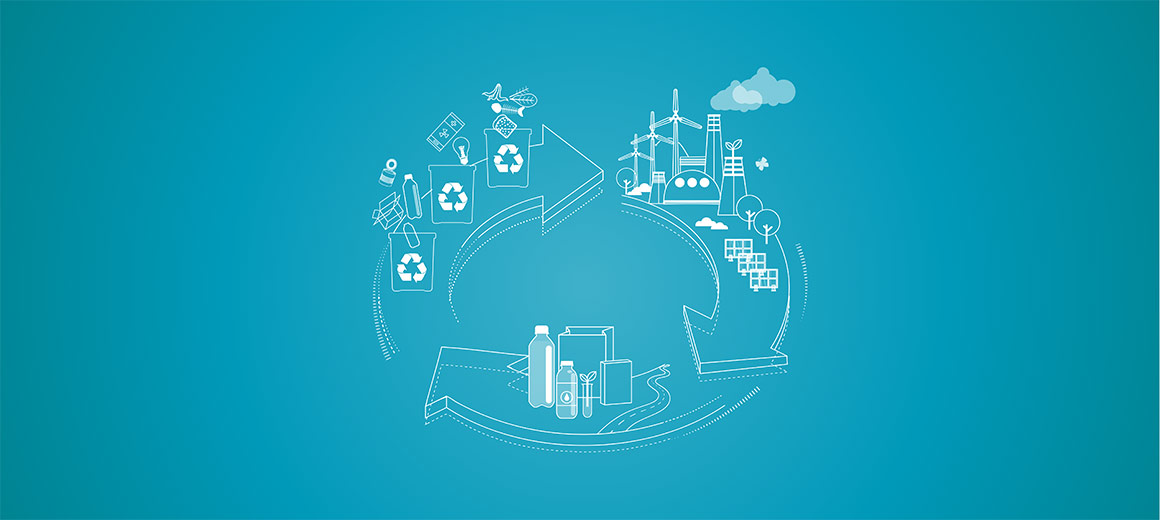

As it’s one of industry’s favourite concepts at the moment, we thought it might be interesting to take a look at how the team at Cool & Heat is responding to the demands of the ‘circular economy’. Working towards the elimination of waste and the continual use of resources, we review how we are committed to reusing, sharing, repairing, refurbishing, remanufacturing and recycling.

All our work, from installation through to maintenance, is designed around installing relevant and efficient systems as well as keeping equipment at peak condition for longer, achieving improved productivity. Moving away from the traditional approach of a linear economy – ‘take, make, dispose’ we’re also focused on recovering resources for re-use. It’s an approach that is increasingly gaining hold, and we’re seeing customers actively asking about our stance in this arena.

We resolved some time ago to concentrate on a more sustainable focus into the future. Concepts like industrial ecology, resource depletion and environmental pollution are now firmly on our radar, and we have adopted and implemented practices in compliance with PAS 99:2012, ISO 45001:2018, ISO 14001:2015 and ISO 9001:2015.

As contractors, we can only make a difference in the areas of a project which come under our direct control. However, we can impact positively on our supply chain. We only use a handful of suppliers who are thoroughly vetted and meet our strict criteria in terms of product sourcing, staff management, and national and international accreditations.

From cradle to grave

Our commitment begins at design stage. We typically design systems for defined life cycles, so we begin by asking the relevant questions of our customers. What does the future hold for this space? How will the system be controlled? Are we future proofing for further down the line, where the company may support an increased workforce or changing needs? This latter is an increasingly important question following the coronavirus pandemic and the shift to working from home.

Our aim is to establish where the customer’s commitment lies. Long warranties? High levels of efficiency? We always try to provide two defined options; one is the best solution in terms of operational efficiencies and the environment, with a secondary option around budgetary limitations. It’s worth pointing out that over the total life cycle of a system, the option requiring more initial investment may well turn out to be more economical in the long term based on running costs and environmental impact.

Once the system is designed, we source the relevant materials and components. We ensure everything we design is has a long life span for optimum reliability and serviceability. Maintenance is always included for the first year. Where we are commissioned to provide a maintenance programme, our affiliations with major manufacturers mean we can provide extended warranties and keep systems at peak performance over the life cycle of the equipment.

Planning for efficiency

We pre-plan everything, including logistics. Parts are delivered to site, to engineers’ homes and to local depots to avoid double shipping; last year, 90% of all materials/components were delivered direct to site.

We provide rigorous maintenance regimes ahead of each major season (winter/summer) together with deep cleans and paperwork management in line with today’s compliance regulations. All this work helps to ensure systems continue to operate at maximum efficiency and levels of environmental safety.

End of life and decommissioning is also an important issue. We look carefully at materials already installed to see what can be re-used, with the objective of saving money for our customers and reducing environmental impact. In some cases, replacing a system may simply mean new outdoor units; our relationship with major manufacturers enables us to offer this option to customers without impacting upon warranties.

Cool & Heat holds a waste carriers’ licence, with all waste recorded and disposed of in line with requirements and standards. We have cut down massively on plastics and use power washers in place of less environmentally acceptable aerosols. All tools calibrated twice yearly.

In short, we have looked carefully at every aspect of the business to improve our ongoing commitment to sustainability and the circular economy. It’s not a one-off approach; we regularly review where we stand and implement new processes to improve our performance. We may not be able to promise a ‘closed loop’ system just yet, but we’re determined to implement all practical options for continuous improvement.